A continuous process

of transforming events into data

to optimize resources.

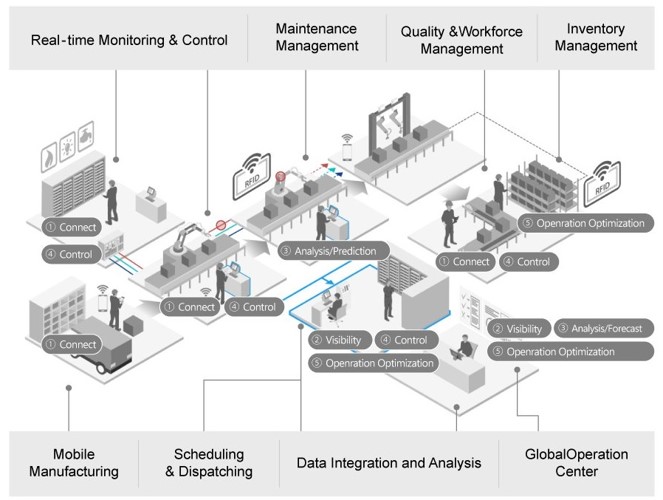

The Role of ControlMES Manufacturing Execution System

Capture real-time shop-floor data, turn it into clear, actionable insights, and enable managers to make smart, timely decisions — driving faster and higher-quality production.

- counter_1Connect & remotely control equipments.

- counter_2Collect real-time production data.

- counter_3Production visualization.

- counter_4Analyze & predict (early detection).

- counter_5Optimize manufacturing operations.

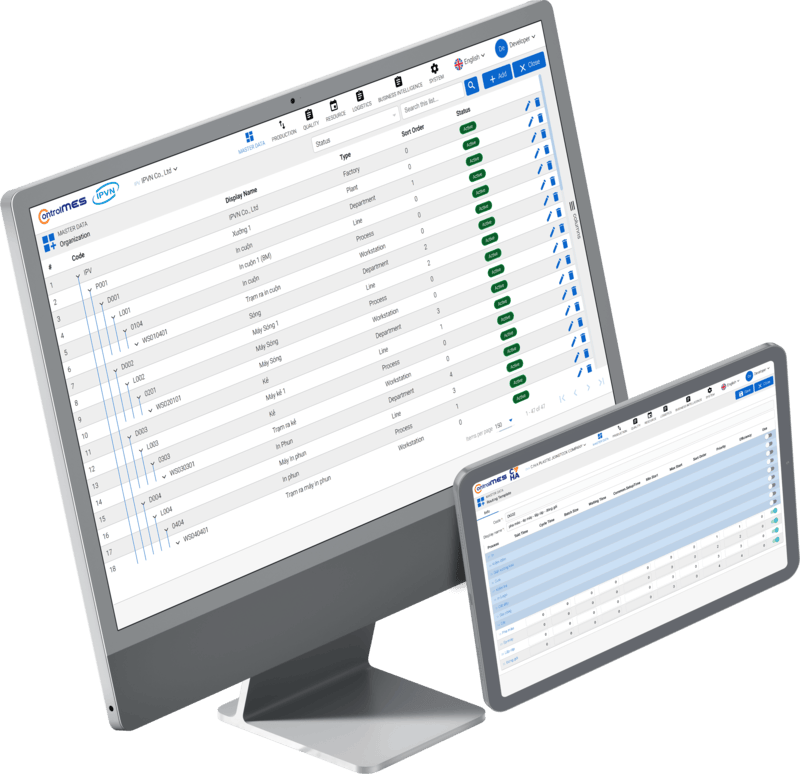

01. Production Planning & Scheduling

Go beyond simple scheduling — deeply optimize production reality to minimize waste, boost throughput, and secure on-time delivery, a critical success factor in manufacturing.

- circle Plan by customer orders and product specifications.

- circle Multi-step planning across production lines.

- circle Optimize production schedules to reduce waste.

- circle Detailed material planning for each production step.

- circle Rapid rescheduling in case of incidents or changes.

- circle Performance analytics on planning effectiveness.

- circle Integration with ERP and warehouse systems.

02. Real-Time Production Monitoring

The core of ControlMES: reflect live shop-floor status so managers instantly know what is happening in the factory.

- circle Track order progress in real time.

- circle Monitor machine and line status.

- circle Monitor production performance (OEE).

- circle Real-time dashboard and shop-floor display screens.

- circle Log downtime causes, delays, and quality issues.

- circle Track actual material consumption.

- circle Instant reports and live charts.

03. Comprehensive Quality Management

Enforce standard operating procedures, monitor product quality metrics, and trigger corrective actions immediately when deviations occur.

- circle Define quality standards.

- circle Perform IQC, in-process (PQC), and OQC inspections.

- circle Manage defects and perform root-cause analysis.

- circle Manage rework processes.

- circle Link production data for full traceability.

- circle Perform statistical quality analysis.

- circle Generate comprehensive quality reports.

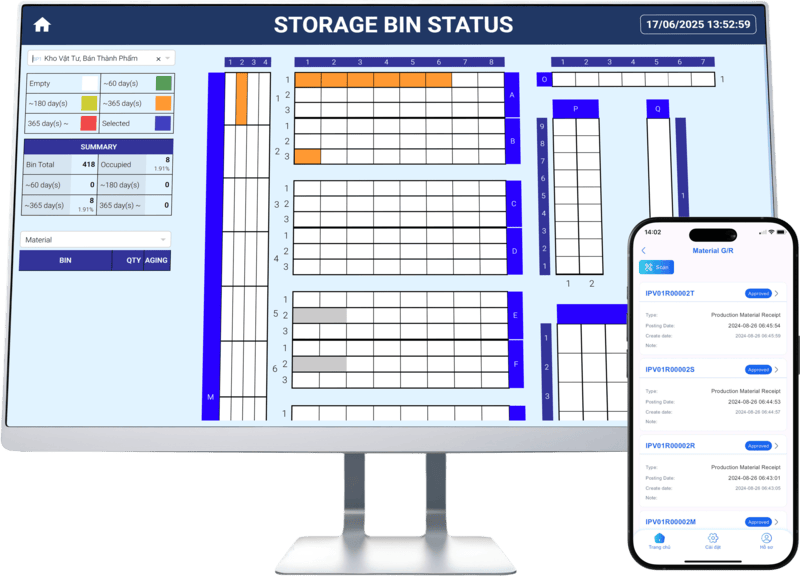

04. Material Flow Management

The crucial bridge between warehouse, production, and quality — ensuring materials are always available, at the right place, right time, and right specification.

- circle Receive and allocate materials.

- circle Track material movement across the shop floor.

- circle Manage material usage by production step.

- circle Automatically calculate consumption and detect variances.

- circle Integrate with scales, sensors, and label printers.

- circle Manage reverse material flow (scrap, re-use).

- circle Enable traceability integration.

- circle Connect to ERP and central warehouse systems.

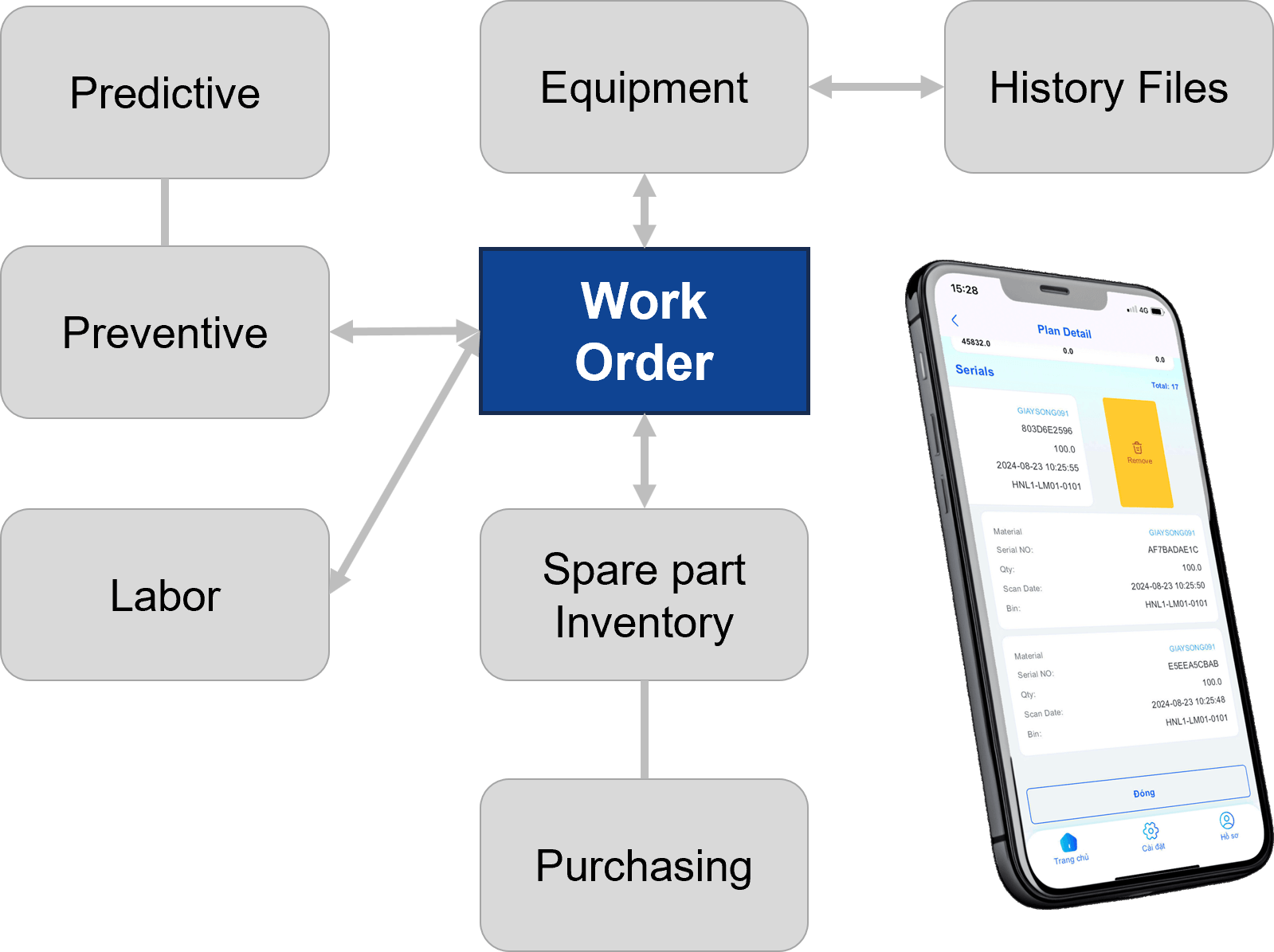

05. Equipment Maintenance Management

Transform from reactive to proactive maintenance, and from time-based to condition-based strategies — maximizing equipment uptime and extending asset life.

- circle Manage equipment inventory and hierarchy.

- circle Plan and schedule preventive maintenance.

- circle Track unplanned maintenance and breakdowns.

- circle Enable condition-based maintenance.

- circle Manage maintenance requests and work orders.

- circle Track spare parts and consumables.

- circle Maintain equipment and maintenance history.

- circle Generate maintenance performance analytics.

- circle Role-based access and electronic sign-off.

06. Factory Resource Management

Ensure optimal allocation of human resources, machines, tools, molds, and fixtures — reducing downtime and maximizing overall plant productivity.

- circle Manage production workforce.

- circle Monitor machine and equipment availability.

- circle Plan and allocate resources efficiently.

- circle Manage tools, molds, and jigs.

- circle Measure resource utilization and performance.

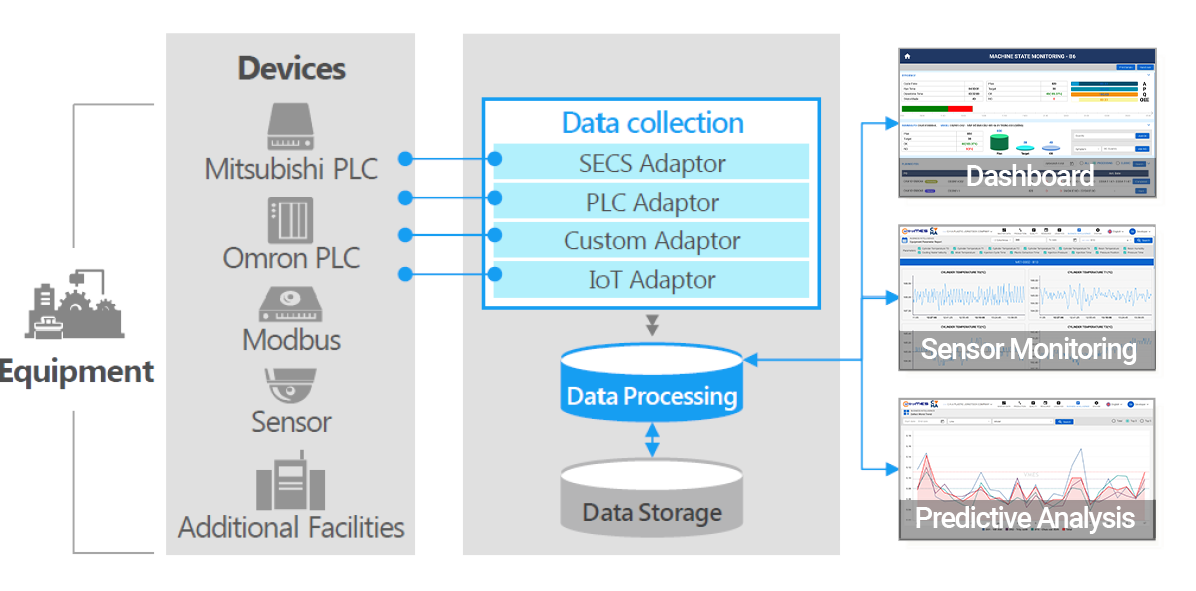

07. Machine Connectivity

The bridge between the physical world (machines, sensors, devices) and digital management — enabling automation, real-time monitoring, and true smart manufacturing.

- circle Communicate with machines via OPC UA, Modbus TCP/RTU, MTConnect, Siemens S7, EtherNet/IP, etc.

- circle Collect production data in real time.

- circle Analyze equipment status (OEE, downtime, anomalies).

- circle Connect to auxiliary devices.

- circle Generate automatic alerts & equipment logs.

- circle Integrate with SCADA, IoT, and cloud platforms.

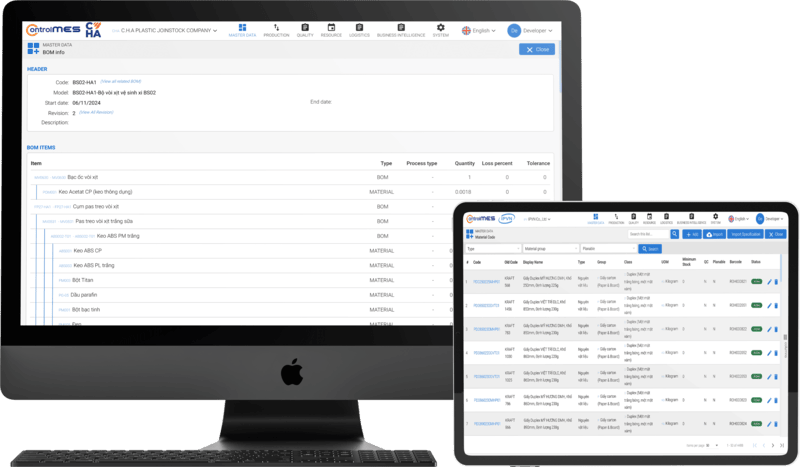

08. Master Data Management

The single source of truth for synchronized, accurate production data — powering planning, operations, monitoring, reporting, and analytics across ControlMES.

- circle Products.

- circle Processes & operations.

- circle Machines & equipment.

- circle Materials.

- circle BOM and BOM levels.

- circle Personnel & roles.

- circle Quality parameters.

- circle Shift patterns and holidays.

- circle Defect symptoms & Defect causes.

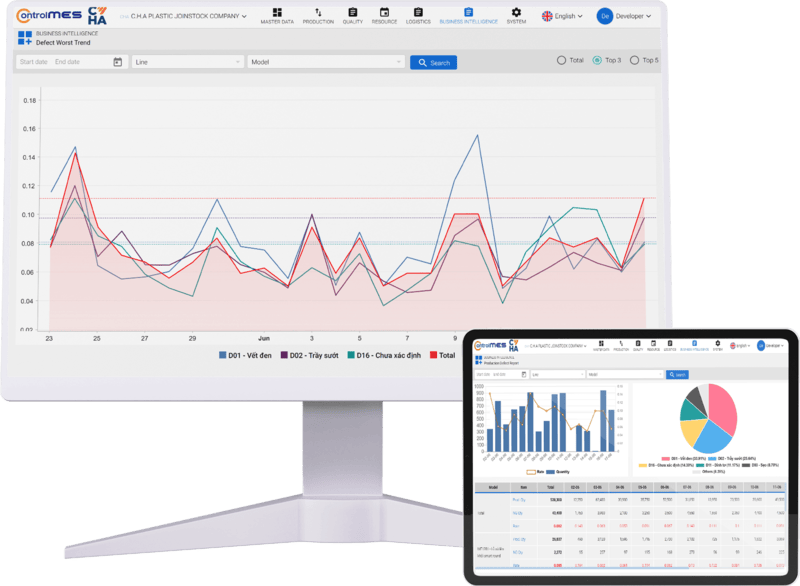

09. Reporting & Analytics

The “brain” of ControlMES — turning real-time production data into clear, actionable insights. Get a bird’s-eye view of the entire factory while drilling into every bottleneck in detail.

- circle Historical reports & trend analysis.

- circle Proactive & smart alerts.

- circle Root-cause analysis.

- circle Customizable reports & data filters.

- circle Integration with BI or ERP systems.

- counter_1 Increasing production complexity?

- counter_2 Demand for real-time data?

- counter_3 Need for consistent product quality?

- counter_4 Planning to scale production?

- counter_5 Compliance and audit pressure?

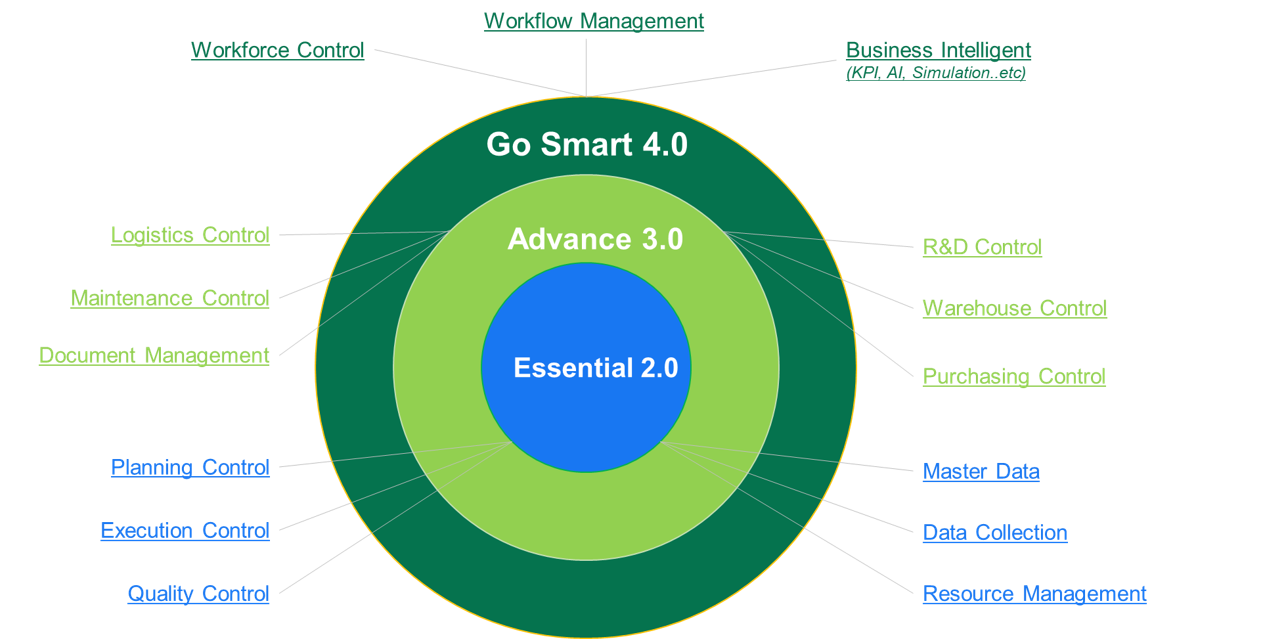

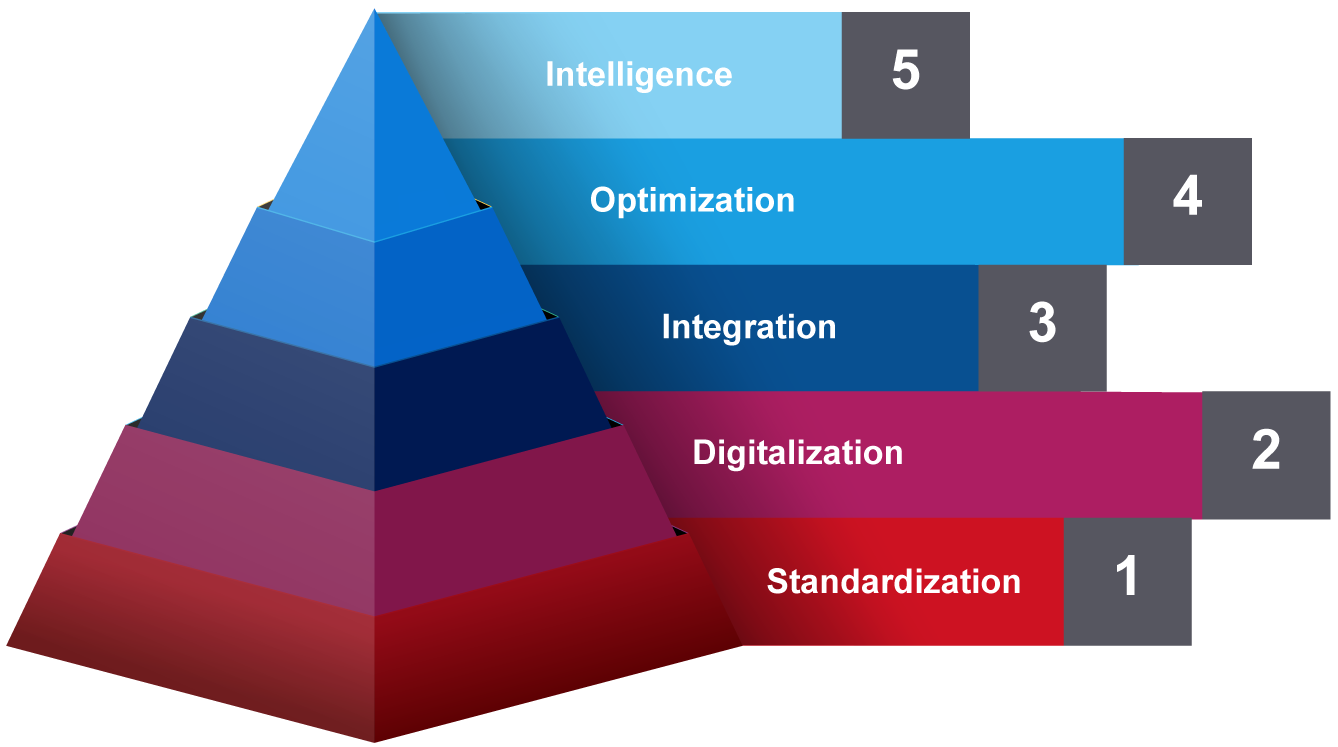

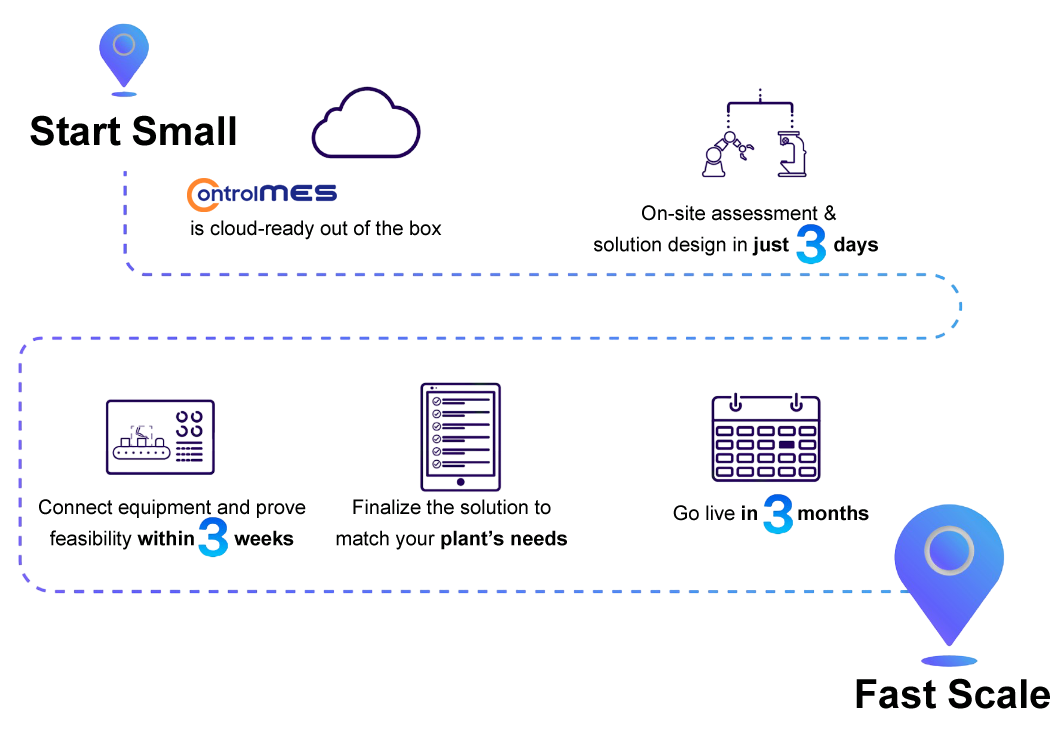

Upgrade & Expand

With an open and modular design, the system is built to support all future upgrades and expansions according to each factory’s unique needs.